EuGenius SW for laser control Automator

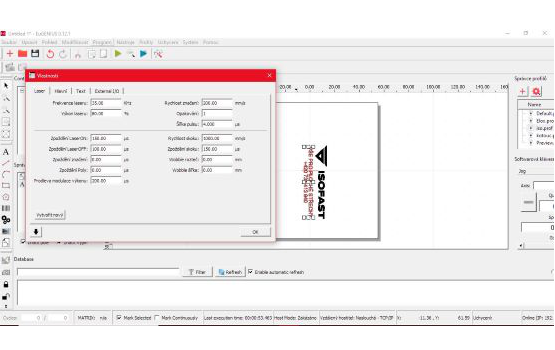

The EuGenius™ application software from our own programming workshop is used to control Automator lasers of II. generation. The development of its own program is another logical step of the Automator (IT) manufacturer in accordance with the intentions of technological development and product innovations. The implementation of interesting functions and an intuitive interface make EuGenius™ a powerful tool for managing the settings and communication of the laser system with the environment.

In addition to the basic functions for working with texts, codes and graphics, the user has extra parameters for setting the laser power such as output power, pulse width, frequency, etc. You can mark all types of codes such as barcode, Datamatrix, GS1 code, QR code .

The EuGenius™ application software from our own programming workshop is used to control Automator lasers of II. generation. The development of its own program is another logical step of the Automator (IT) manufacturer in accordance with the intentions of technological development and product innovations. The implementation of interesting functions and an intuitive interface make EuGenius™ a powerful tool for managing the settings and communication of the laser system with the environment.

In addition to the basic functions for working with texts, codes and graphics, the user has extra parameters for setting the laser power such as output power, pulse width, frequency, etc. You can mark all types of codes such as barcode, Datamatrix, GS1 code, QR code .

Simply ingenious software!

Advanced features that will please users include:

- QuickTest (quick test of project settings and I / O signals)

- Perfect focus (red contour marking contours)

- Counting of marking cycles (used for back-checking the number of marking)

- Export marking history (export to .xlsx file)

The laser can be controlled via a PC interface. In the case of unattended operation, it is possible to connect the laser to the so-called „stand-alone“ mode, the data for marking is then obtained from the production information system or other peripheral equipment or database.

For industrial applications, the communication interface Profinet and others can be used.

The software is localized into Czech and other 20 languages and is delivered including the user manual.

Advanced features that will please users include:

- QuickTest (quick test of project settings and I / O signals)

- Perfect focus (red contour marking contours)

- Counting of marking cycles (used for back-checking the number of marking)

- Export marking history (export to .xlsx file)

The laser can be controlled via a PC interface. In the case of unattended operation, it is possible to connect the laser to the so-called „stand-alone“ mode, the data for marking is then obtained from the production information system or other peripheral equipment or database.

For industrial applications, the communication interface Profinet and others can be used.

The software is localized into Czech and other 20 languages and is delivered including the user manual.